Beam Clamps / Clips

Beam clamps are essential hardware used to safely mount and suspend various systems from structural steel. Whether you’re running conduit, installing ceiling grids, hanging ductwork, or supporting cable trays, beam clamps provide a secure anchoring point without needing to drill or weld the beam itself. This makes them an ideal solution across trades where overhead installation is required.

At Hook & Hanger, we stock a wide selection of beam clamps designed for real-world conditions, ranging from knock-on, hammer-on, screw-on, and spring steel options. These clamps work with different flange thicknesses and threaded rod sizes, supporting both light-duty and heavy-duty systems with fast, non-invasive installation.

- FM24 - Knock-on Beam Clamp for Flanges 1/8" - 1/4" Thick by Doc's Industries Inc. FM24 (1PC)$0.92 (each)

- FM58 - Knock-on Beam Clamp for Flanges 5/16" - 1/2" Thick by Doc's Industries Inc. FM58 (1PC)$0.94 (each)

- HOK-24 - Knock-On Beam Clamp for Flanges 1/8 - 1/4" Thick by Doc's Industries Inc. HOK-24 (1PC)$0.52 (each)

- HOK-58 - Knock-On Beam Clamp for Flanges 5/16" - 1/2" Thick by Doc's Industries Inc. HOK-58 (1PC)$0.59 (each)

- HOK2414TI - Hammer-on beam clamp assembled to 1/4"-20 threaded rod hanger clip by Doc's Industries Inc. HOK2414TIAs low as $1.57

- HOK2438TI - Hammer-on beam clamp assembled to 3/8"-16 threaded rod hanger clip by Doc's Industries Inc. HOK2438TIAs low as $1.59

- HOK5814TI - Hammer-on beam clamp assembled to 1/4"-20 threaded rod hanger clip by Doc's Industries Inc. HOK5814TIAs low as $1.77

- HOK5838TI - Hammer-on beam clamp assembled to 3/8"-16 threaded rod hanger clip by Doc's Industries Inc. HOK5838TIAs low as $1.78

- HOKFMP - Hammer-on Beam Clamp for Flanges 1/8" - 1/2" Thick by Doc's Industries Inc. HOKFMP (1PC)$1.31 (each)

Why Beam Clamps Are Critical in Overhead Suspension Work

In overhead installations, safety and speed are critical. Beam clamps allow contractors to mount systems directly to I-beams or bar joists without altering the structure. This preserves the load-bearing capacity of the steel and meets code compliance for non-penetrative fastening. For jobs where time and labour costs are tight, beam clamps help installers move faster without compromising quality or security.

Beam clamps are frequently used in commercial ceilings, mechanical rooms, industrial plants, and utility spaces. They’re also commonly used in overhead drilling and anchoring projects where non-penetrative fastening is essential. Because many models can be installed using just a hammer or a few hand tools, they reduce fatigue, improve safety during high-access work, and simplify retrofits or maintenance tasks. Beam clamps are equally valuable in temporary and permanent installations, offering the flexibility to relocate or reuse hardware as needed.

Types of Beam Clamps and Their Applications

At Hook & Hanger, our product range includes multiple clamp types tailored to specific flange sizes, installation styles, and accessories.

One of the most widely used styles is the knock-on beam clamp. These are installed by sliding the clamp over the flange and tapping it into place using a hammer. Standard knock-on models in our collection fit flanges ranging from 1/8 inch to 1/4 inch thick. These lighter-duty options are ideal for suspending ceiling wire, jack chain, or bridle rings in ceiling grid systems or low-load installations. For flanges measuring between 5/16 inch and 1/2 inch thick, we offer medium-duty knock-on clamps that provide a firmer grip, making them suitable for heavier fixture drops or longer rod spans.

Some knock-on variants also include dual-threaded holes, typically 1/4"-20 that allow installers to attach multiple components, such as ceiling wire and bridle rings, without additional fasteners. There are also models with through-holes that support jack chain or 1/4-inch bolts, giving installers flexibility to mount across different system types.

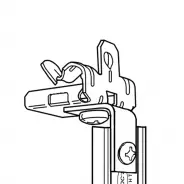

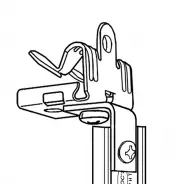

For more demanding applications, the hammer-on beam clamp is a great option. These clamps are installed by striking them directly onto the beam flange, creating a secure grip through mechanical tension. We carry hammer-on models designed for flange thicknesses ranging from 1/8 inch to 1/2 inch. Many of these clamps come pre-assembled with threaded rod hanger clips compatible with standard rod sizes such as 1/4"-20 or 3/8"-16. That means you can mount your rod immediately after installation without needing additional hardware or adapters.

One of our most popular hammer-on clamps supports both 1/4 inch and 3/8 inch threaded rod sizes and fits securely on flanges up to 1/2 inch thick. These are commonly used in projects that involve pipe bracketing, cable tray suspensions, or electrical conduit drops in industrial buildings or warehouses.

We also offer unassembled hammer-on options like the HOKFMP-style beam clamp. This model fits flanges between 1/8 inch and 1/2 inch and is designed to be installed with a single hammer strike. It’s compatible with threaded bridle rings, #10–24 accessories, and other overhead wire supports. These clamps are ideal for electricians and ceiling contractors who need quick setups across beam spans without the need for drilling or threading tools. When paired with extension poles, they allow overhead work to be completed from the ground level safely and efficiently.

For precise alignment and heavier-duty support, our adjustable screw-on beam clamp is a smart choice. Made from zinc-plated steel, this clamp features tapped holes on both the side and bottom for secure threaded rod installation. It supports flange widths up to 1/2 inch and is typically used with 1/4"-20 threaded rods. This screw-on clamp allows for more controlled placement and is perfect when alignment, spacing, or weight distribution needs to be fine-tuned.

Lastly, the spring steel beam clamp offers a lightweight and highly flexible option. This clamp is designed to grip flanges from 1/8 inch to 1/2 inch thick and works well with bridle rings, conduit clips, ceiling wire, or S-hooks. Despite its lower profile, the spring steel clamp maintains strong tension and is capable of supporting medium-duty installations. It is especially useful in confined areas where rigid clamps may not fit or where vibration resistance is important.

Material Strength and Load Performance of Beam Clamps

The strength and longevity of a beam clamp largely depend on the material used in its construction. At Hook & Hanger, our clamps are fabricated from high-quality zinc-plated steel, spring steel, and corrosion-resistant alloys to ensure long-term durability in demanding environments.

Zinc-plated steel provides reliable strength while offering basic protection against corrosion. This makes it well-suited for indoor commercial applications, such as retail spaces, offices, and schools. The smooth coating also makes installation easier by reducing friction as the clamp is positioned over the flange.

Spring steel, on the other hand, is more flexible and lightweight while still offering strong grip pressure. This material is ideal for use in fast-paced ceiling or cable installations where adaptability and ease of use are more important than raw load capacity.

Across the range, our clamps are designed to accommodate a variety of load requirements. Light-duty clamps, such as knock-on models for 1/8" flanges, are intended for lighter fixtures and wire. Medium-duty clamps with a larger flange range up to 1/2 inch offer improved strength for longer rod drops and mechanical supports. Adjustable screw-on clamps provide the most stability for heavier mechanical or pipe support systems and are engineered for precise, weight-distributed mounting.

Compatibility with Rods and Accessories

All of our beam clamps are designed with real-world compatibility in mind. Most models work with standard 1/4"-20 or 3/8"-16 threaded rod fasteners, the most common sizes used in suspended ceiling, electrical, and HVAC systems. Clamps with dual threaded holes allow multiple rod attachments or the combination of rods and ceiling wire for hybrid support setups.

Pre-assembled hammer-on clamps in our collection feature integrated rod hangers matched to these thread sizes, making them job-ready out of the box. This eliminates the need to thread components on-site and helps speed up installation time.

In addition to rod support, many clamps accommodate jack chain, ceiling wire, bridle rings, and S-hooks. Some configurations also work in conjunction with angle clips when precise bracing or edge mounting is required. Some versions include side holes, top holes, or universal slots that accept a wider variety of fasteners, offering flexibility for mixed-use projects or unusual mounting requirements.

Spring steel clamps are especially versatile, often supporting both threaded and unthreaded accessories. Their tension-grip design ensures that even in dynamic conditions, like air handling vibrations or slight rod movement, they remain firmly in place.

Common Uses for Beam Clamps in Construction and Building Services

Beam clamps are used in nearly every trade that deals with overhead mounting. Their role in making the ceiling, mechanical, and utility systems safe and accessible is essential.

In electrical installations, beam clamps are regularly used to suspend EMT conduit, junction boxes, bridle rings, and cable trays. Because they provide secure mounting without altering the beam, they’re preferred in code-compliant commercial electrical systems.

HVAC contractors use beam clamps to hang ductwork, condensate lines, flexible piping, and air distribution systems. When working above finished ceilings or in tight ceiling voids, hammer-on or adjustable clamps provide the stability needed for long-term mechanical installations.

Ceiling grid contractors rely on knock-on clamps to anchor suspension wires in suspended ceiling systems to steel beams or bar joists. Their fast installation makes them ideal for jobs that require repetitive mounting across large open-plan spaces like schools, offices, and shopping centers.

Beam clamps can also be used to anchor purlin clips across open-span metal joists in ceiling installations.

In mechanical and plumbing trades, adjustable screw-on clamps are used to build rod-hung trapeze systems for pipe racks, fire protection lines, or equipment frames. Because they allow for precision placement and load-bearing alignment, they’re often specified in hospital, laboratory, and plant construction.

Even facility maintenance teams use beam clamps for temporary installations or quick replacements in lighting, signage, and cable management pathways. Since beam clamps leave no damage when removed, they’re also well-suited to leased properties or phased construction.

Safety Considerations and Installation Tips

Proper use of beam clamps starts with selecting the right size and style for the beam and application. Always match the clamp’s rated flange thickness and load capacity to the job’s requirements. Using an undersized clamp or exceeding the load rating can result in slippage, system failure, or damage to the structure.

Before installation, inspect each clamp for damage or signs of corrosion, especially around the threads, hinge points, or mounting holes. A worn or damaged clamp should never be reused.

For knock-on clamps, ensure that the clamp is fully seated on the flange and tapped into position without excessive force. Overdriving a clamp can damage its tension arms or deform the flange. For hammer-on types, strike only as recommended and make sure the clamp is installed straight on the flange face. For screw-on models, tighten the set screw or bolt until firm contact is made, but avoid over-torquing.

Always confirm that rods and accessories are properly threaded, aligned, and tensioned. Misaligned attachments can introduce side-loading or vibration that compromises long-term performance.

Compliance and Environmental Assurance

All beam clamps available at Hook & Hanger are produced using high-quality materials under environmentally responsible manufacturing practices. Most of our clamps are RoHS compliant, meaning they are free from hazardous substances like lead, mercury, cadmium, and certain flame retardants. This makes them suitable for use in public buildings, healthcare facilities, and sustainable construction projects.

Where applicable, certain clamp designs may also carry additional certifications such as UL listing or ANSI conformance.

Beam Clamps for Modern Construction Needs

Today’s construction industry is increasingly modular, fast-paced, and regulation-driven. Beam clamps fit naturally into this environment by offering non-invasive, reusable, and quick-install fastening solutions. Whether you’re coordinating layout in BIM or working with off-site fabrication, having access to universal hardware like beam clamps keeps installations on track and adaptable to change.

Need Help Finding the Right Beam Clamp?

At Hook & Hanger, we offer a complete line of knock-on beam clamps, hammer-on beam clamps, adjustable screw-on clamps, and spring steel clamps to support your overhead installation needs. Whether you're mounting threaded rods, supporting conduits, or building mechanical hangers, our clamps are designed for real-world conditions and fast-paced jobs.