Metal / Plastic J Hooks

Versatile Metal / Plastic J Hooks; Ideal for Low Voltage Cable Support

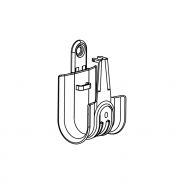

Our HPH (High Performance Hybrid) Metal / Plastic J Hooks are built using the perfect amalgamation of metal and polymer. The U-shaped plastic component has a thick base that provides support to the cables without placing them under stress, while the metal spine acts as a sturdy backbone. The innovative ‘strap-lock’ retainer is also very convenient and easy to use. Our HPH J-Hooks are UL listed, RoHS compliant, TIA compliant, and plenum rated, making them one of the most versatile cable management solutions on the market.

- HPHAC Series J-Hook - Composite Wide Base Hook with 90° angle clip for 1/4" rod by Doc's Industries Inc. HPHACAs low as $73.18 (Pk25)

- HPHEC14 Series J-Hook - Composite Wide Base Hook with 1/4"-20 Female Thread Eye Coupling by Doc's Industries Inc. HPHEC14As low as $75.47 (Pk25)

- HPHPM Series J-Hook - Composite Wide Base Hook w Magnet - 10 pack by Doc's Industries Inc. HPHPMAs low as $86.92 (Pk10)

- HPHPMSM Series J-Hook - Composite Wide Base Hook w Magnet - 10 pack by Doc's Industries Inc. HPHPMSMAs low as $85.18 (Pk10)

Large & Small Heavy Duty J-Hooks

Cable management is a science of its own. A wrongly assembled cable system can be disruptive, unsightly, and even dangerous. J-Hooks are designed specifically to provide you with a cleaner and more organized workspace. Its ingenious design has completely revolutionized the cable management system.

We have provided a detailed guide on our High-Performance Hybrid (HPH) J-Hooks below to help you understand how these little devices can help make your life easier.

What Are Doc's High Performance Hybrid Metal / Plastic J-Hooks?

Telecommunication rooms typically consist of a maze of cables, which usually end up looking like a tangled mess. Simple tasks, like swapping a hard drive, suddenly become time-consuming and challenging. This is where efficient cable management systems come into play.

J-Hooks are a great alternative to raceways and cable trays, which are usually much more expensive and cumbersome to use. As the name suggests, the profile of the J-Hooks is shaped like the letter ‘J.’ They are available in various sizes; however, 2-inch and 4-inch J-Hooks are the most common.

Our specially designed HPH J-Hooks are made from galvanized steel nestled in a specially designed polymer casing. The metal-plastic hybrid design offers the best of both worlds. The plastic U-shaped structure provides a smooth base, which minimizes stress on the supported cables. The base is also designed with an efficient bend radius, which provides a slick and burr-free surface.

The metal backbone adds to the robustness of the J-hook system, providing the necessary load capacity for heavy-duty cabling. This smart combination of materials allows our HPH J-Hooks to be as light as possible for ease of installation, without sacrificing strength and durability.

J-Hooks are highly preferred over other cable management variants because of their flexibility, ease of reconfiguration, and speed of installation. Another reason to opt for J-Hooks is their economical pricing in comparison to other systems.

1, 2, 3 & 4 Inch J-Hooks - which to use and when....

Do you often find yourself amidst a tangled web of cables? Would you like to make more efficient use of your office space? Do your existing plastic hooks break all the time due to excessive usage?

If your answer is ‘yes’ to any of the above questions, then our J-Hooks are the ideal solution to your problems.

Our HPH J-Hooks provide optimal support for telecommunication, high-speed data (Cat 5e, Cat 6, Cat 6A, Cat 7), and fiber optic cables. Basically, any data communication and low voltage cables can be managed with our hook systems.

The plastic-metal composite construction ensures that our J-Hooks are strong enough to support substantial structured cabling systems. Our 4-Inch J-Hooks, for example, can safely carry up to 300 4-pair UTP CAT 5e or 2-strand fiber optic cables. These numbers far exceed the capacity of traditional plastic J-Hooks, making it ideal for heavy-duty applications. This unique structural composition also allows them to be used for both indoor and outdoor installations.

Additionally, managing cables means dealing with hard to reach nooks and low corners. Our smart-sized HPH J-Hooks squeeze in anywhere and fit comfortably. They are available in four different sizes, ranging from ¾-inch to 4-inch, and can be used in various combinations depending on your needs.

The efficiency of our Hybrid Metal / Plastic J-Hooks

What sets our J-Hooks apart from the competition is their well-thought-out and innovative design.

In most conventional plastic or PVC J-Hooks, bends in the cable can be problematic. These hooks have thin bases with a flat geometry, which can create kinks in sagging cables. These kinks form areas of high stress, which can degrade the cabling over time and lead to breaks.

The polymer body of our HPH J-Hook has a broader base to provide extra support to bulky cables. Furthermore, the base is designed with an optimum bend radius, which minimizes stress concentrations in the cable, ensuring their integrity and longevity.

Another major challenge faced by installers while using traditional J-Hooks is the clumsy tie-in system. Most heavy-duty J-Hooks and plastic J-Hooks use retainer wires, Velcro straps, or finicky cables ties to secure the cords.

This is where our HPH J-Hooks offer the perfect solution. The innovative built-in ‘snap-lock’ latch makes it convenient to secure the cables in hard-to-reach areas. This smart locking system also makes rearranging wires much easier and stress-free. All you have to do is unsnap the lock, change the cable, and then snap again to close the system!

Small & Large, Heavy Duty J-Hook Attachments

In addition to the smart features of our design, our J-Hooks also come with numerous attachments to allow for easier installation on a variety of surfaces, rods, wires, or beams.

Our HPH J-Hooks come pre-assembled with some of the most common fasteners, like batwings, beam clamps, and 90° angle clips. We have a range of magnetic attaching options as well for temporary installations. We basically have you covered from all sides to make your installation as easy as possible!

Installing Our Heavy Duty, Large or Small J-Hooks

J-Hooks are relatively easy to install, and with proper attachment fittings, pivoting becomes a cakewalk. Researches show that J-Hooks can yield labor savings up to 75%, which makes it preferable to other alternative cable management devices. See our detailed instructions to find out how to install our HPH series J-Hooks.

It is recommended to use the best practices below when installing your J-Hooks for efficient cable management.

- Try to maintain a 4 to 5 feet spacing interval between J-Hooks.

- Ensure that the cables do not sag more than 1 foot when laid over the J-Hook.

- Close all snap-lock retainers to secure the cables in place.

- Make sure the overall appearance of the J-Hook system is neat with minimal twisting and distortion.

Are Our High Performance Hybrid Metal/Plastic J-Hooks Industry Compliant?

We are proud to say that our HPH J-Hooks are some of the best-designed and compliant cable management products on the market. They meet (and in some cases exceed) industry standards, such as TIA, RoHS, cULus.

For instance, our HPH J-Hooks provide a much larger bend radius compared to the industry average of 3.57 inches, thus, exceeding TIA’s bend radius standards. This bend radius is especially crucial for high-performance cables like Cat6, Cat6a, Cat7, and fiber optic cables.

The ‘wide base’ design makes our J-Hooks ideal for routing sensitive data cables. The increased support width prevents indentations, pinches, creasing, and other cable deformations.

Our products are also plenum compliant for use in air-handling spaces, and all pre-assembled attachments are UL listed to guarantee safety and quality compliance.

Our HPH J-Hooks offer a unique cable management experience, which makes us unbeatable in the industry. Our goal is to ensure that you never have to struggle with messy cables ever again!

If you would like to know more about how our J-Hooks can improve your cable management experience, feel free to contact our support team today!